Rubber roofing systems like EPDM are known for their durability and weather resistance. However, after years of exposure to sun, rain, and fluctuating temperatures, even these tough membranes can begin to show signs of wear. That’s where rubber roof coating comes in, a cost-effective way to extend the life of your flat roof and improve its performance.

At JM Roofing Solutions, we specialize in rubber roof coating services for commercial and industrial properties. Whether you’re looking to restore your current roof or proactively protect it from future damage, our expert team has the tools and experience to get the job done right.

JM Roofing Solutions offers professional rubber roof coating services in Lansing, MI. Call us today at (269) 361-8305 to schedule your consultation and protect your investment.

Why Consider Rubber Roof Coating?

Rubber roof coating is a highly effective solution for rejuvenating aging EPDM or other rubber roofing systems. Applied as a liquid membrane, it forms a seamless, flexible barrier that bonds directly to the existing roof surface. This protective layer fills minor cracks, smooths over imperfections, and helps restore the integrity of your roof without requiring a full tear-off.

Coatings are particularly valuable for commercial and industrial buildings where downtime must be minimized. Not only does this method provide an extra layer of waterproofing, but it also adds reflectivity that enhances your building’s energy efficiency year-round.

Key benefits include:

- Extended Lifespan: A professionally applied coating can extend your rubber roof’s life by 10 to 15 years, helping you delay the need for a full replacement.

- Improved Energy Efficiency: Reflective coatings like acrylic or silicone deflect UV rays, reducing rooftop heat absorption and lowering your cooling costs, especially beneficial during Lansing’s hot summers.

- Seamless Protection: The liquid-applied system creates a continuous, watertight surface that effectively guards against leaks, ponding water, and severe weather.

- Cost Savings: Compared to a full roof replacement, coating is far more affordable and requires less labor and materials, making it a smart financial choice for budget-conscious property owners.

- Minimal Disruption: With no need for tear-off or extensive demolition, roof coating projects are completed quickly and quietly, perfect for facilities that need to stay operational during the process.

Rubber roof coating is a strategic investment that pays off in both immediate savings and long-term performance. For many Lansing property owners, it’s the ideal solution to extend roof life without the expense of full replacement.

The Coating Process

At JM Roofing Solutions, we follow a meticulous, step-by-step process to ensure your rubber roof receives a high-performance coating that delivers lasting protection and value. Every stage is designed to maximize adhesion, improve energy efficiency, and extend the life of your roofing system, while minimizing disruption to your business.

Inspection and Evaluation

We begin with a comprehensive roof inspection to assess the condition of your existing rubber or EPDM surface. Our experts look for issues such as membrane shrinkage, ponding water, seam separation, and punctures. We also determine whether your roof is a good candidate for coating or if more extensive repairs are necessary beforehand.

Cleaning and Preparation

Proper surface preparation is critical to long-lasting results. We power wash the entire roof to eliminate dirt, oils, mold, algae, and oxidation. Any loose or lifting membrane sections are securely re-adhered. We then repair small cracks, open seams, and flashing vulnerabilities to ensure the surface is uniform and ready for coating.

Primer Application (If Needed)

For older or more porous rubber roofs, we apply a specialty primer designed to improve adhesion between the existing surface and the new coating. This step ensures the coating bonds properly and enhances overall durability, especially on weathered or chalky materials.

Coating Installation

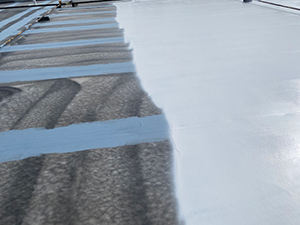

Using top-tier silicone or acrylic coatings, we apply the product in a uniform layer across the entire surface. Our team pays close attention to details, sealing around roof penetrations, flashing, edges, seams, and drainage points. This creates a seamless, watertight membrane that protects against leaks, UV exposure, and temperature extremes.

Final Quality Check

Once the coating has fully cured, we perform a final walk-through to inspect coverage thickness, adhesion quality, and water resistance. Our team ensures every inch of your roof has been treated properly and is ready to withstand the elements for years to come.

This thorough process not only restores the protective qualities of your rubber roof but also helps reduce cooling costs, improve building performance, and avoid the expense of a full roof replacement. With proper maintenance, a newly coated roof can deliver reliable protection for a decade or more.

Rubber Roof Coating Services

JM Roofing Solutions provides expert rubber roof coating services in Lansing, MI, ideal for Michigan’s harsh and shifting climate. Rubber coatings flex with temperature changes, standing up to hot summers, freezing winters, and heavy snow without cracking. Call us today at (269) 361-8305 to protect your roof year-round.

FAQ

How long does rubber roof coating last?

A quality rubber roof coating can last between 10–15 years, depending on the product used and maintenance practices.

Can all rubber roofs be coated?

Most EPDM or rubber roofs can be coated if they are structurally sound. A detailed inspection will determine if repairs or replacement are a better option.

Is roof coating better than roof replacement?

For many flat roof systems, coating is a cost-effective alternative that avoids the disruption and expense of full replacement—especially when the roof is still structurally viable.